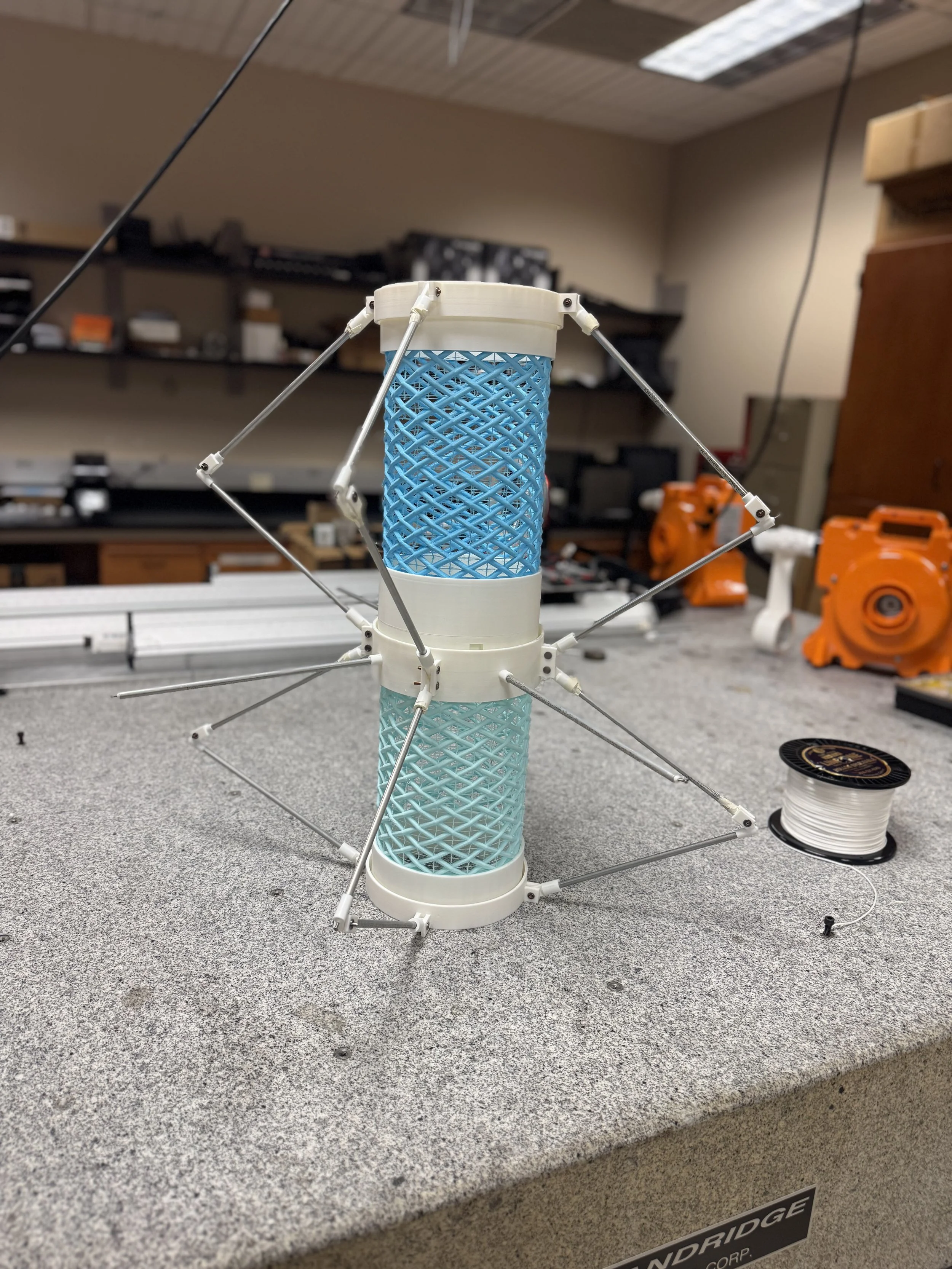

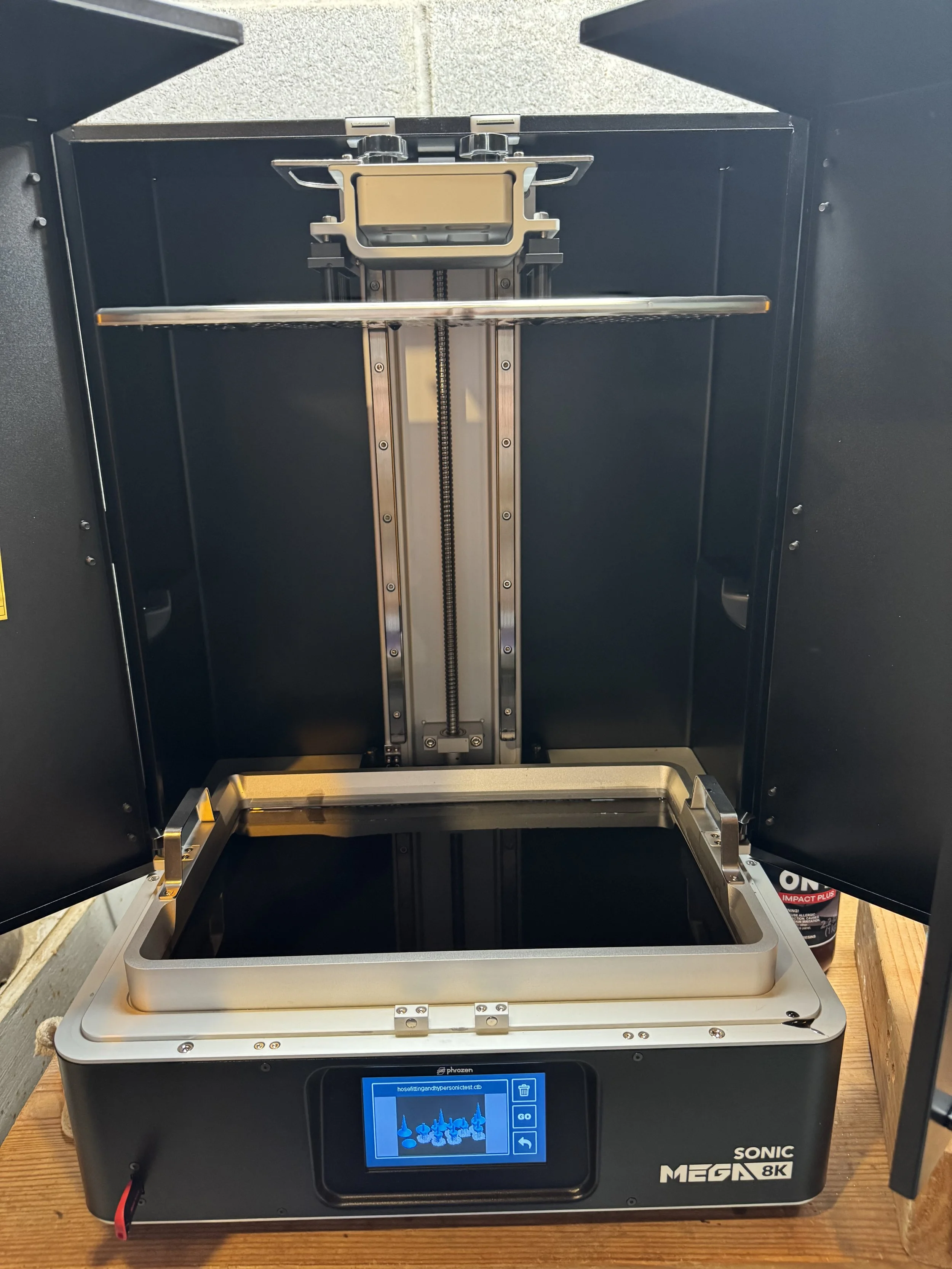

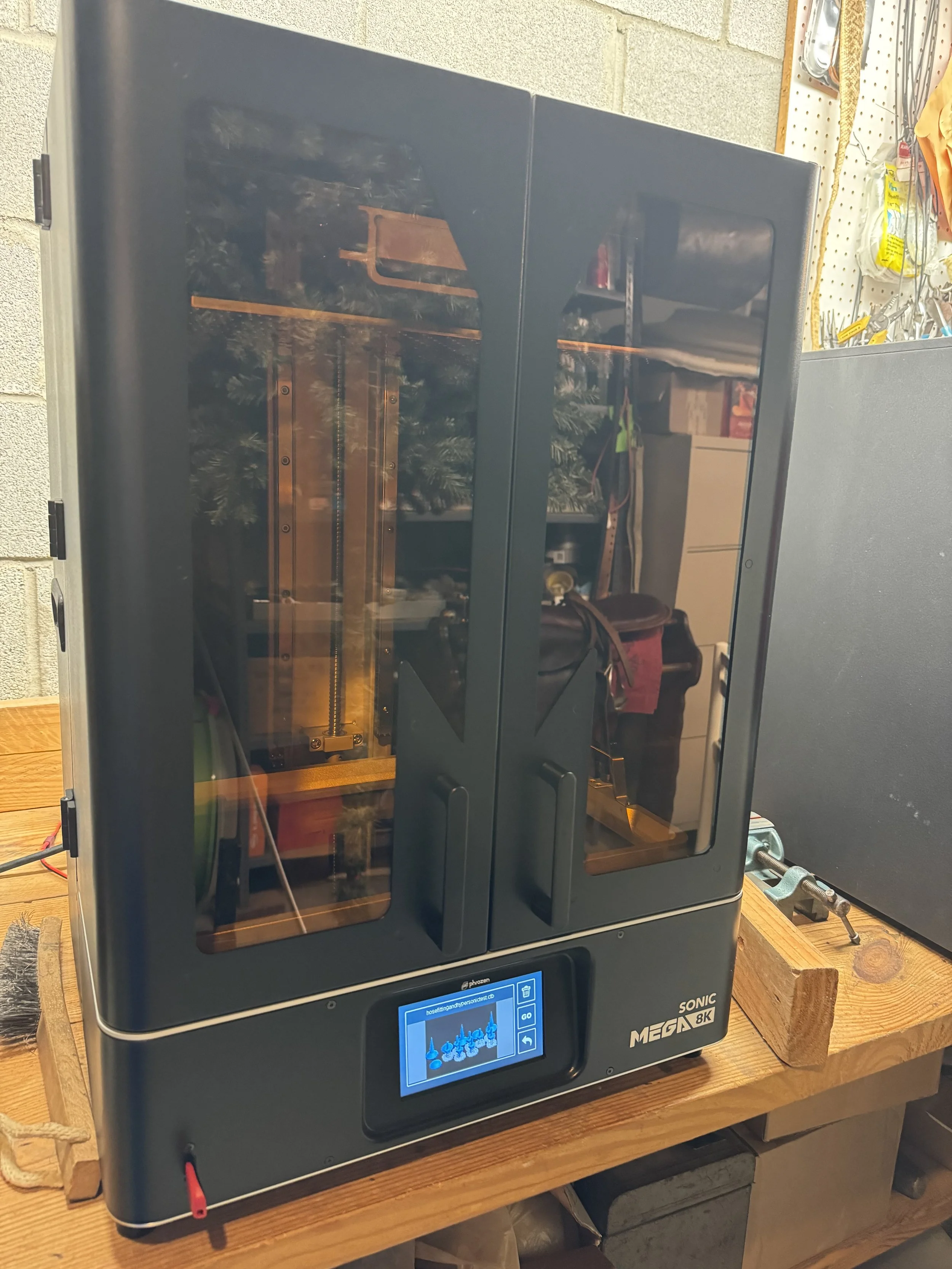

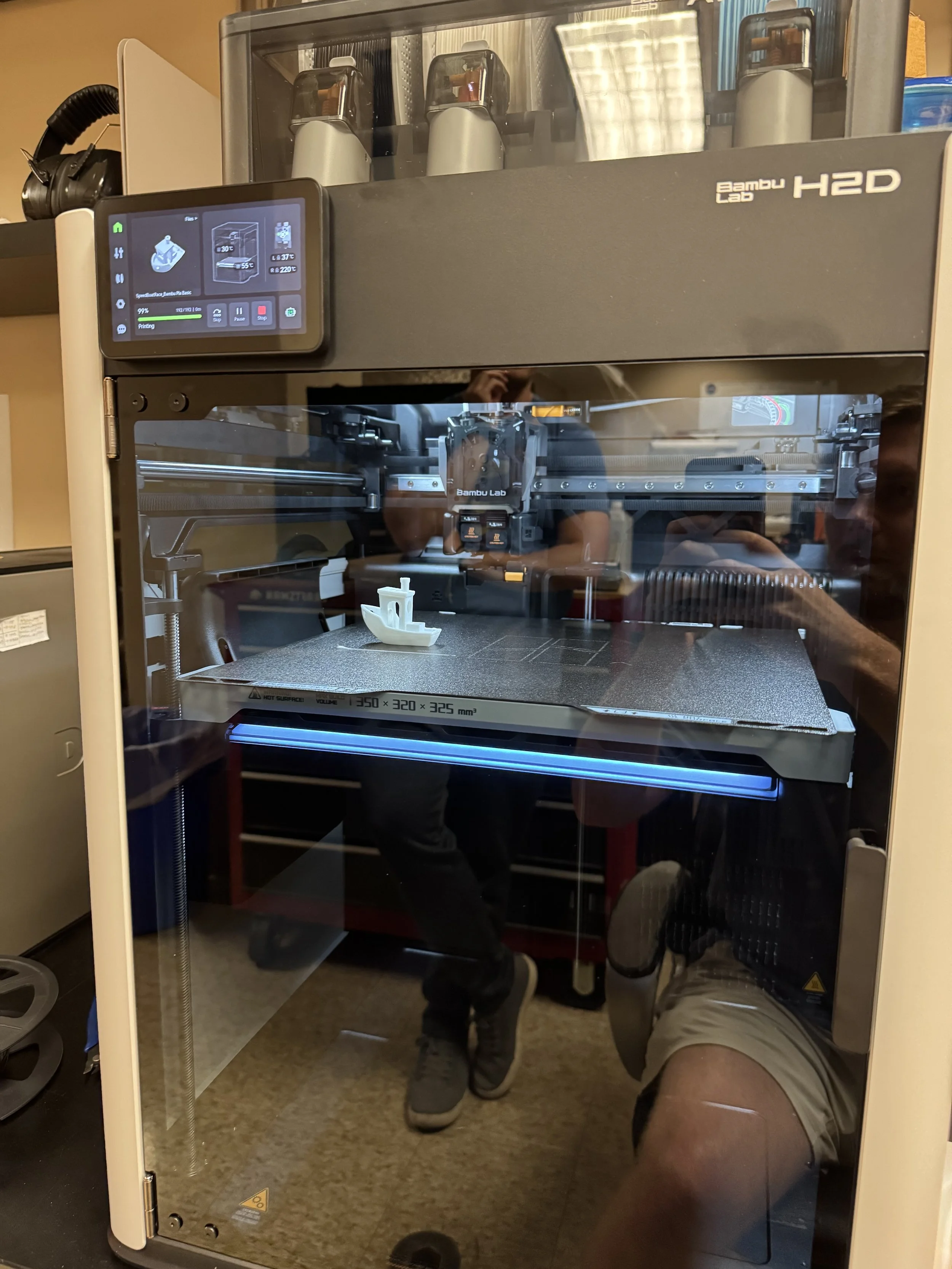

I have extensive experience in additive manufacturing, specializing in Fused Deposition Modeling (FDM) and Stereolithography (SLA) technologies. Proficient in optimizing print parameters for diverse filaments including PLA, ABS, PETG, TPU, and composites like carbon fiber-infused variants, as well as engineering-grade resins such as tough, flexible, high-temperature, and biocompatible formulations. Experience spans printer calibration, slicer software mastery (e.g., Cura, PrusaSlicer, Chitubox), and custom support structure design to minimize material waste and post-processing while ensuring structural integrity. Hands-on operation of large-format systems up to 800mm x 800mm x 1000mm build volumes, addressing challenges like thermal management, bed adhesion, and multi-part assembly in scaled prototypes. Utilized a range of printers including all Bambu Lab models (e.g., X1 Carbon for high-speed precision), Prusa series (MK4S to XL for reliability in iterative prototyping), Formlabs Form 2/3/4 for high-resolution SLA in medical and industrial applications, and Phrozen Mega 8K for ultra-detailed large-scale resin prints.

Key skills and techniques:

- Parameter Optimization: Fine-tuning layer height (0.001-1mm), infill density (10-100%), print speed (20-600mm/s), nozzle temperature (180-310°C for FDM; UV intensity/exposure times for SLA), and cooling profiles to balance speed, strength, and surface finish.

- Material Selection and Handling: Expertise in filament/resin properties—viscosity, shrinkage, tensile strength-enabling applications from flexible wearables to rigid aerospace components; includes moisture control, storage, and recycling protocols.

- Support Structure Engineering: Designing minimal-contact supports, tree-like branches, or soluble PVA/HIPS for complex geometries; automated generation and manual refinement to reduce scarring and support removal time.

- Printer Tuning and Maintenance: Bed leveling, PID tuning, belt tensioning, and firmware upgrades; troubleshooting issues like warping, stringing, layer shifts, and resin contamination for 99%+ success rates.

- Large-Format Scaling: Managing thermal gradients in oversized builds, multi-zone heating, and enclosure modifications; experience with segmented prints and assembly for prototypes exceeding standard volumes.

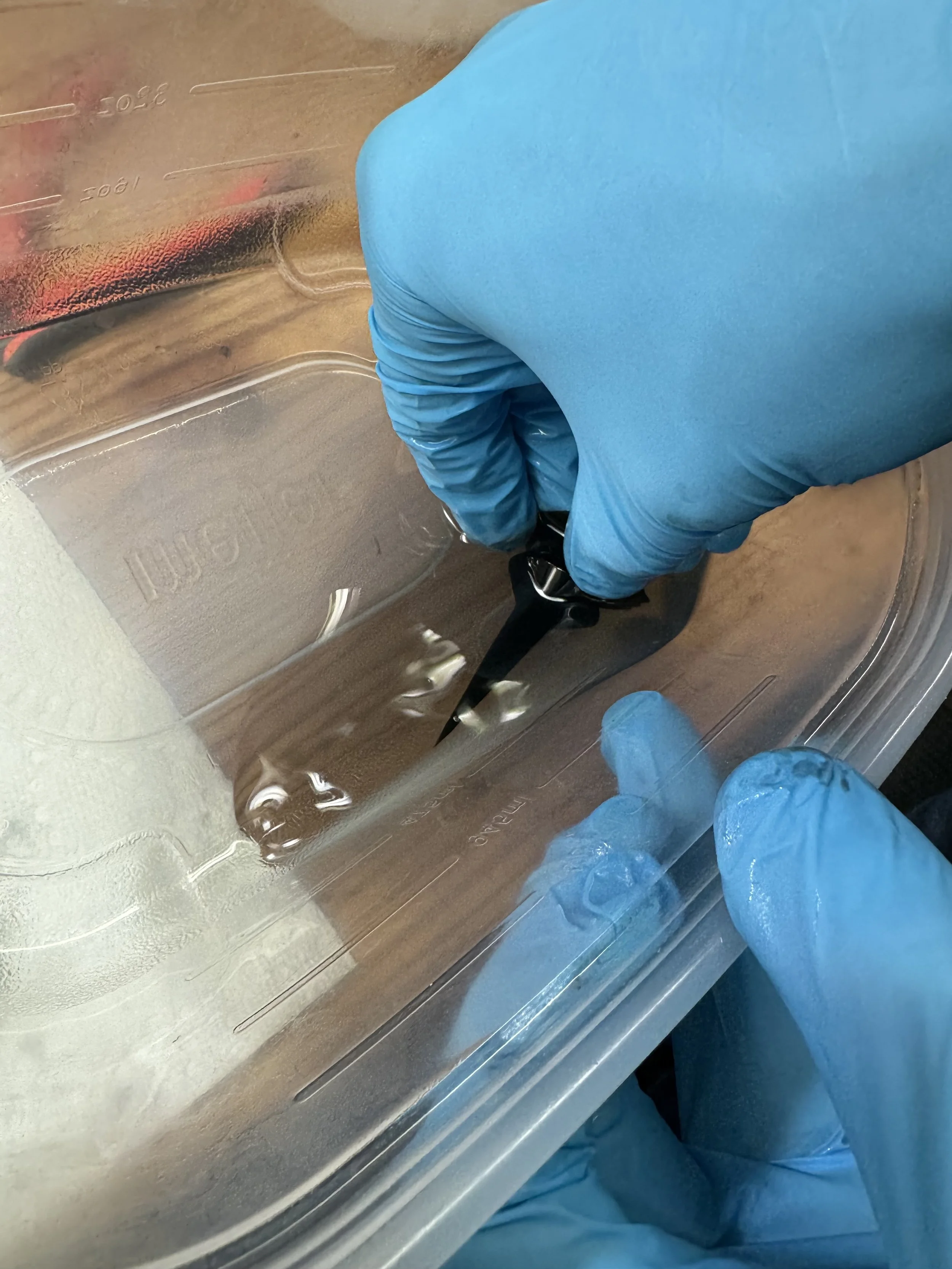

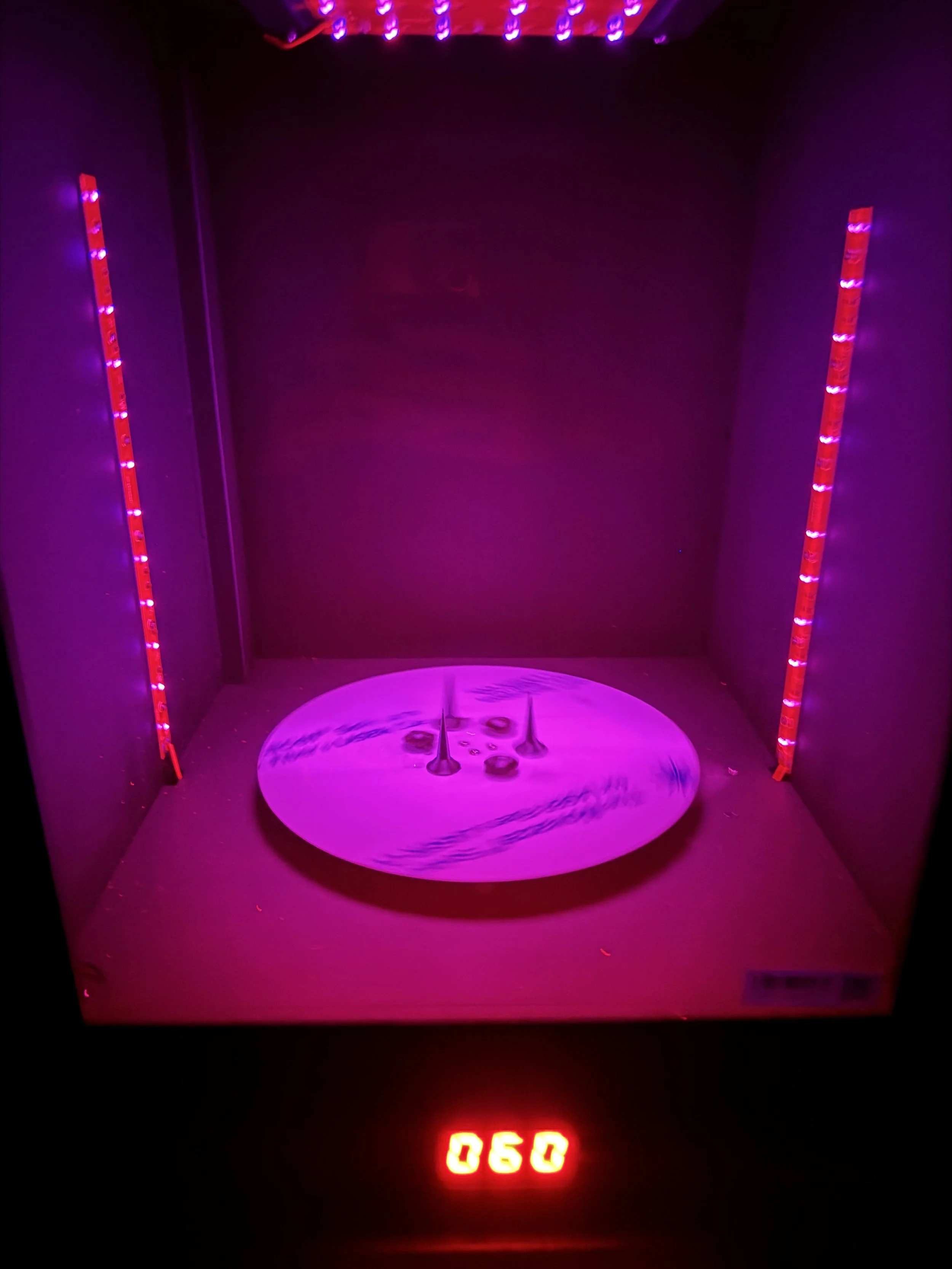

- Post-Processing Techniques: Vapor smoothing, sanding, priming, and coating for FDM; IPA washing, UV curing, and support clipping for SLA; integration with CNC milling for hybrid manufacturing.

- Software Integration: Advanced use of CAD (Fusion 360, SolidWorks) for model preparation, simulation of print failures via FEA, and API scripting for automated batch processing.